Blue Wave Semiconductors Unveils DEAR MPCVD System: A Breakthrough in CVD Diamond Research and Applications

Diamond Exploratory & Applied Research Microwave Plasma CVD (DEAR-MPCVD)

MD, UNITED STATES, February 5, 2025 /EINPresswire.com/ -- Blue Wave Semiconductors presented its latest innovation, the Diamond Exploratory and Applied Research Microwave Plasma Chemical Vapor Deposition (DEAR MPCVD) system, at the Materials Research Society’s Fall Meeting in Boston, MA, 2024. According to Dr. R.D. Vispute, CEO & CTO of Blue Wave Semiconductors, the DEAR MPCVD system represents the future of CVD diamond research, offering a versatile and efficient platform for exploratory and applied research in diamond-based technologies.Diamond, a wide-bandgap material, is a cornerstone for next-generation technologies, including quantum energy generation, sensing, and advanced electronics. High-quality thin films for device applications can be fabricated using Chemical Vapor Deposition (CVD) techniques. Among these, Microwave Plasma CVD (MPCVD) reactors are the most widely used for diamond growth. To enhance the properties of diamonds for electronic and quantum applications, doping is required, which can be achieved using in-situ CVD growth with the flow of dopant gas or by the ion implantation method. However, ion implantation introduces defects in the diamond lattice, making the CVD approach more suitable for device fabrication, scalability, and high-quality diamond growth.

In this direction, Blue Wave Semiconductors (BWS) has designed and developed an optimized microwave cavity that supports a larger diameter quartz tube with differential pumping vacuum seals, multiple optical viewports for temperature, plasma process, and growth monitoring, and a sample stage that creates efficient microwave plasma above the substrate (substrate size up to 12 mm x 12 mm). The system operates with various gas flow ratios, a wide range of deposition pressures, and substrate temperatures ranging from 650°C to 1100°C, enabling the deposition of homoepitaxial, large-grain microcrystalline, and nanocrystalline CVD diamond films for a variety of applications.

The DEAR MPCVD system uses microwave power ranging from 650 W to 1.5 kW, achieving growth rates from 0.2 microns/hr to over 10 µm/hr. These advancements elevate the BWS CVD tool to a commercial level, surpassing early reports by the National Institute for Research in Inorganic Materials (NIRIM) in Japan in the 1980s and by Cardiff University

The DEAR MPCVD system has a unique central feature, an interchangeable quartz tube that creates a multi-dopant system required for future breakthroughs in quantum and electronic grade diamonds. A wide variety of dopants are possible using this tool including exotic dopants that require high operating pressure due to their high vapor pressures. Blue Wave designed differentially pumped quartz tube adapters specifically for DEAR-MPCVD to address the issues of leak rate and contamination from traditional quartz interfaces.

Key Features of the DEAR MPCVD System:

1. Growth of Diamond on Complex Substrates: Supports homoepitaxial and heteroepitaxial growth for advanced applications.

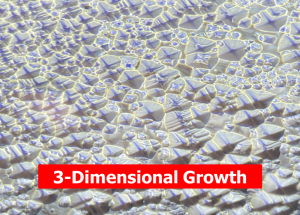

2. Fine-Tuned Parameters for High-Quality Growth: Enables precise control over 2D or 3D growth features for single-crystal diamonds.

3. Versatile Film Growth: Capable of producing polycrystalline, microcrystalline (large grain), and nanocrystalline (smooth surfaces) diamond layers.

4. Multi-Dopant Compatibility: Features an interchangeable quartz tube for dedicated dopant systems, enabling the use of exotic dopants with high vapor pressures in a cost-effective manner.

5. Quantum Research Tools: Purpose-built for studying and harnessing quantum centers in diamonds.

6. Safety Features: Includes a dedicated vented cabinet for mass flow controllers of all gases.

7. Efficient Plasma Formation: Utilizes innovative air- and liquid-cooled microwave resonant cavities.

8. Growth Rate Flexibility: Offers typical growth rates from 0.1 microns/hr to a maximum of 5 microns/hr.

9. Device Development: Ideal for doped epilayers, driving advancements in diamond-based devices.

10. Advanced Surface Processing: Supports hydrogen termination and H₂/O₂ etching & plasma cleaning for improved chemical and electronic properties.

11. In-Situ Monitoring: Possible to optionally advance laser reflectivity for real-time growth process monitoring.

12. Temperature Control: Uses an optical pyrometer for accurate substrate temperature monitoring.

The DEAR MPCVD system has demonstrated high-quality CVD diamond growth using ~1 kW of microwave power. Crystalline samples have been characterized by using Scanning Electron Microscopy (SEM), Electron Backscatter Diffraction (EBSD), XRD, Raman Spectroscopy, and Photoluminescence / Cathodoluminescence at room temperature (RT) and low temperature (LT). Investigated films indicated high-quality single-crystal growth. The system’s plasma characteristics were also studied using Optical Emission Spectroscopy (OES), confirming a controllable C₂/H ratio that balances high quality and high growth rates.

According to Dr. R.D. Vispute who is the founder of Blue Wave Semiconductors:

“Whether it’s quantum centers or doped epilayers, DEAR MPCVD delivers the precision and reliability we need. Hydrogen termination has added new dimensions to our diamond-based studies, delivering results that are beyond expectations. The DEAR MPCVD capability to work in an R&D lab setting is a game-changer in CVD diamond research.”

About Blue Wave Semiconductors:

Blue Wave Semiconductors is a pioneering company specializing in the development of advanced materials and cutting-edge technologies for next-generation applications, including quantum sensing, electronics, and composite materials. The company is a graduate of bwtech@UMBC, a leading technology incubator affiliated with the University of Maryland, Baltimore County (UMBC). bwtech@UMBC provides startups and growing companies with access to state-of-the-art facilities, mentorship, and entrepreneurial resources, fostering innovation and commercialization in cutting-edge technologies. As part of the BWtech and Maryland ecosystem, Blue Wave Semiconductors has leveraged the Maryland M4 grant to develop groundbreaking solutions like the DEAR MPCVD system. To learn more about the DEAR MPCVD system and Blue Wave Semiconductors’ innovative research, visit www.bluewavesemi.com.

Reference 1: M. KAMO, Y. SATO, S. MATSUMOTO and N. SETAKA, J. Cryst. Growth 62 (1982) 642.

Reference 2: E. L. H. THOMAS, L. GINES, S. MANDAL, G. M. KLEMENCIC, and O. A. WILLIAMS, AIP ADVANCES 8, 035325 (2018)

Reference 3: M. G. DONATO, G. FAGGIO, M. MARINELLI, G. MESSINA, E. MILANI, A. PAOLETTI, S. SANTANGELO, A. TUCCIARONE, and G. V. RINATI, Eur. Phys. J. B 20, (2001)

Reference 4: P. N. VOLPE, J. C. ARNAULT, N. TRANCHANT, G. CHICOT, J. PERNOT, F. JOMARD, P. BERGONZO, Diamond & Related Materials 22 (2012)

Ratnakar D Vispute

Blue Wave Semiconductors, INC.

email us here

Visit us on social media:

Facebook

LinkedIn

Instagram

YouTube

Distribution channels: Book Publishing Industry, Chemical Industry, Manufacturing, Military Industry, Technology

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release